One might consider labeling the items you use in your everyday workspace part of the low-hanging fruit when starting in your lean journey. As simple as it seems, it could also be one of the most important. It’s easy to underestimate the time spent looking for a tool, or referencing it against a process checklist to make sure it’s correct.

But, imagine you have been assigned a task that should take about 20 minutes to complete. Your workspace has the equipment necessary, but there are also extra tools, scattered around the workstation. The task should be easy, but you haven’t performed this exact task in the past few months. A good portion of this 20 minutes could be spent just trying to figure out what you need, and what might be missing. A clearly labeled workspace and tool outline in your area would immediately cut down on preparation time and the possibility of rework needed due to the use of an incorrect tool.

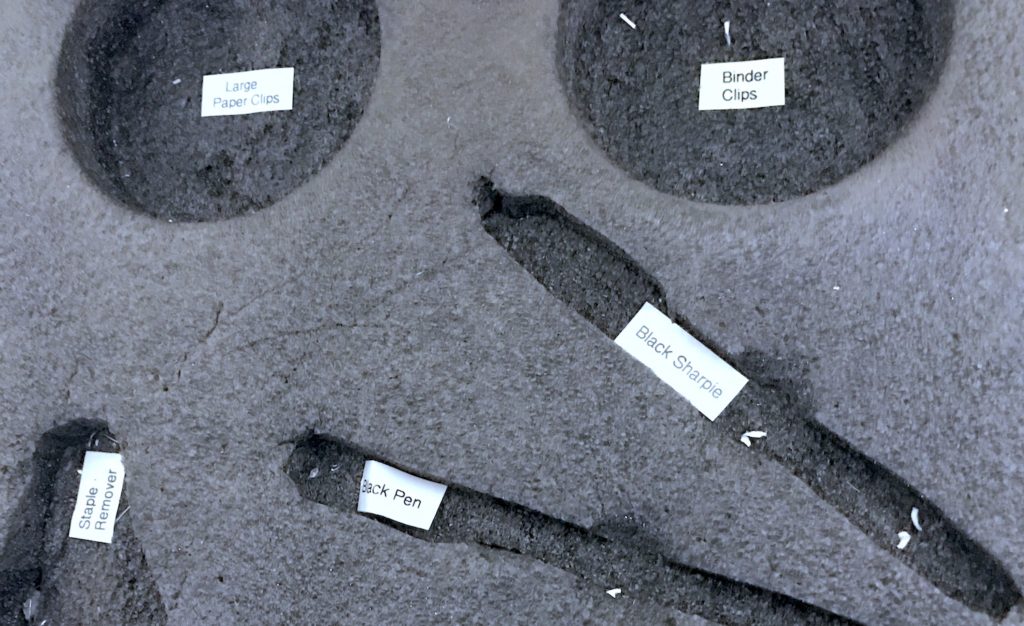

In the video below, Reggie Niesler shows how the labelling of the tool bin helps to “give everything a home” to keep the number of tools in the area at a minimum and provide clear outline of necessary tools needed for that process.

https://youtu.be/hpHJmF7DaCQ

There are also safety and cost aspects associated. With a clear tool outline, you won't have tools that could drop off easily or have sharp edges exposed, assuming they were put back into their tool outline with care. You can prevent unnecessary reordering of parts thought to have gone missing because you know exactly where each tool is. Lastly, imagine the headache you can avoid by having to track everything down. That alone is worth the few minutes with the labeling machine.

This blog discusses the principles brought up in Lean Manufacturing and 2 Second Lean. Make sure to check back often to get tips and Cambridge's POV on lean implementation and its effects on our company and culture.